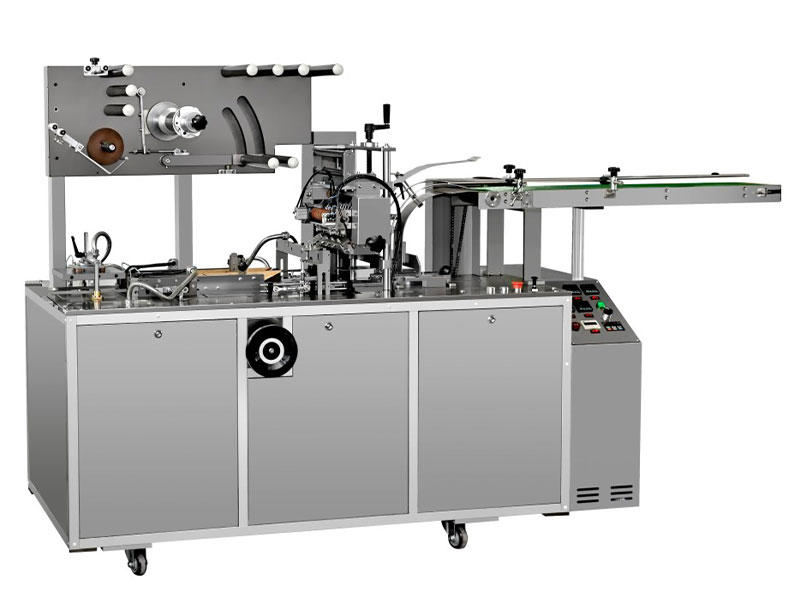

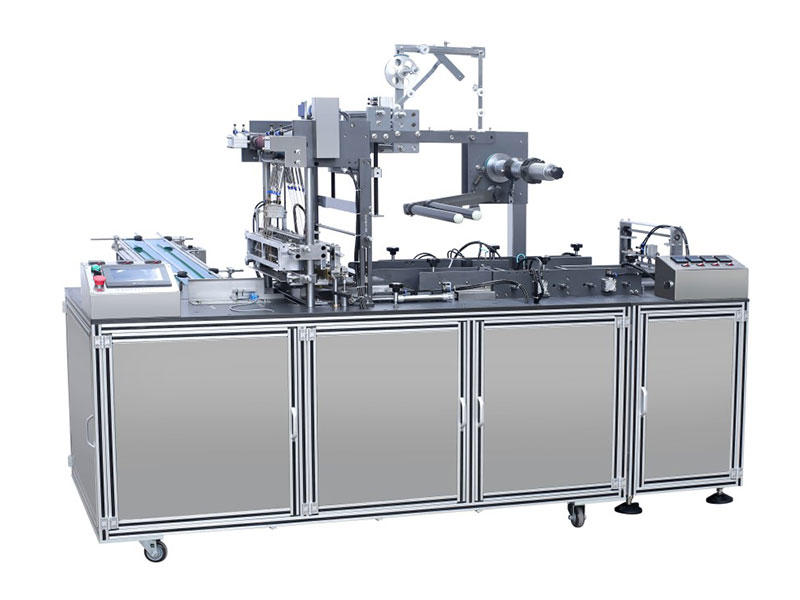

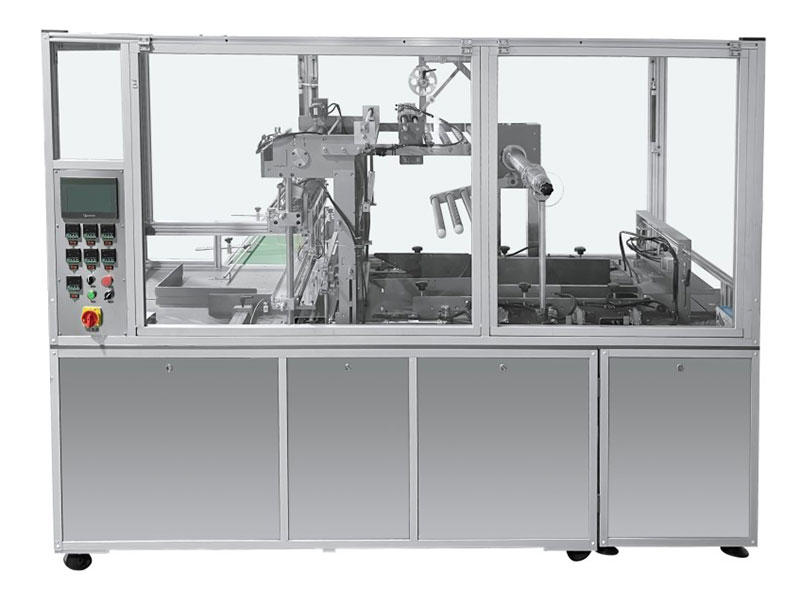

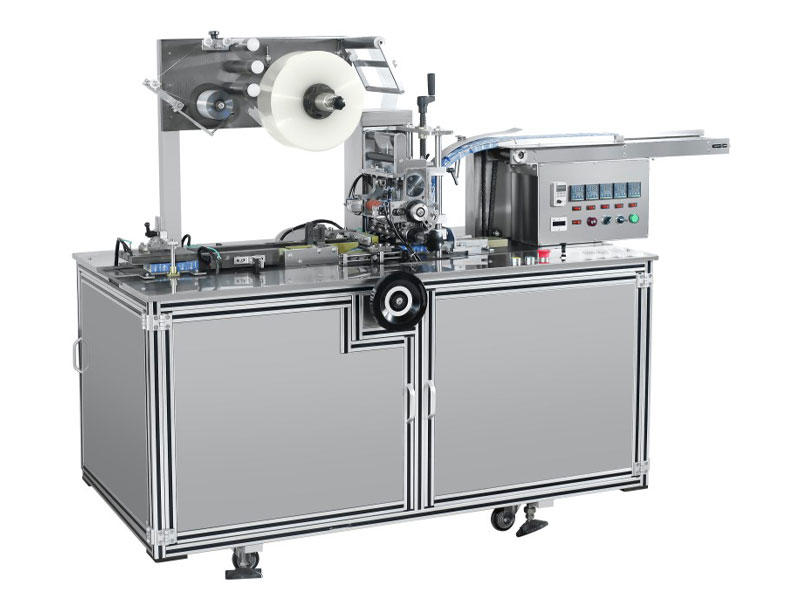

The Small Box Transparent Film 3D packaging machine is designed to wrap products in transparent film that is molded into a three-dimensional shape, creating an attractive and secure packaging solution. This technology is particularly useful for small consumer goods, electronics, cosmetics, food items, and more. The machine typically works by unwinding a roll of film, shaping it to fit the product, and then applying heat and pressure to create a secure seal. The resulting package is durable, visually appealing, and provides protection from external factors such as dust, moisture, and handling damage.

The efficiency and versatility of this machine make it a popular choice in packaging lines, but determining its cost performance requires a comprehensive evaluation of both the initial investment and the ongoing operational costs.

The initial investment in a Small Box Transparent Film 3D packaging machine can vary significantly depending on factors such as the brand, the machine's capacity, and the specific features included. Typically, these machines come in a range of models, from more basic, entry-level machines to high-end, fully automated systems.

For businesses just starting or those with lower packaging volumes, the entry-level models of the Small Box Transparent Film 3D packaging machine may offer a more affordable option. These models are generally simpler in design, with fewer automated functions and a lower output capacity. While the upfront cost is lower, they may require more manual intervention and may not offer the same level of speed and efficiency as higher-end models.

On the other hand, businesses with high-volume production needs or those requiring advanced features such as automatic film alignment, high-speed wrapping, or integration with other packaging equipment may need to opt for a more expensive, fully automated machine. While the initial cost is higher, the increased efficiency and automation can bring about substantial savings in labor costs and increased production rates.

Once a Small Box Transparent Film 3D packaging machine is up and running, operating costs are the next consideration for determining cost performance. The significant operating cost is the film itself, which varies in price depending on the material, thickness, and quality required. Transparent films made from materials like PVC, PET, and PP are commonly used for packaging small products. Businesses must ensure that they select the right film type for their products to avoid unnecessary costs associated with damaged or poorly sealed packaging.

The efficiency of the film usage is another factor that affects operating costs. A well-calibrated Small Box Transparent Film 3D packaging machine minimizes waste by ensuring the correct amount of film is used for each package. In contrast, poorly adjusted machines may use excess film, bring about higher material costs over time. Additionally, regular maintenance and proper machine calibration are necessary to avoid downtime, which could otherwise increase operating costs by reducing the machine's output.

Energy consumption is another key component of operating costs. The heat sealing and molding processes of the Small Box Transparent Film 3D packaging machine require energy, and the energy efficiency of the machine will influence the total running costs. Modern machines tend to be more energy-efficient, incorporating features such as automatic shutdown during periods of inactivity, temperature controls, and energy-saving modes. Businesses should consider the machine's energy consumption when evaluating overall operating costs.

英语

英语 中文简体

中文简体 阿拉伯语

阿拉伯语