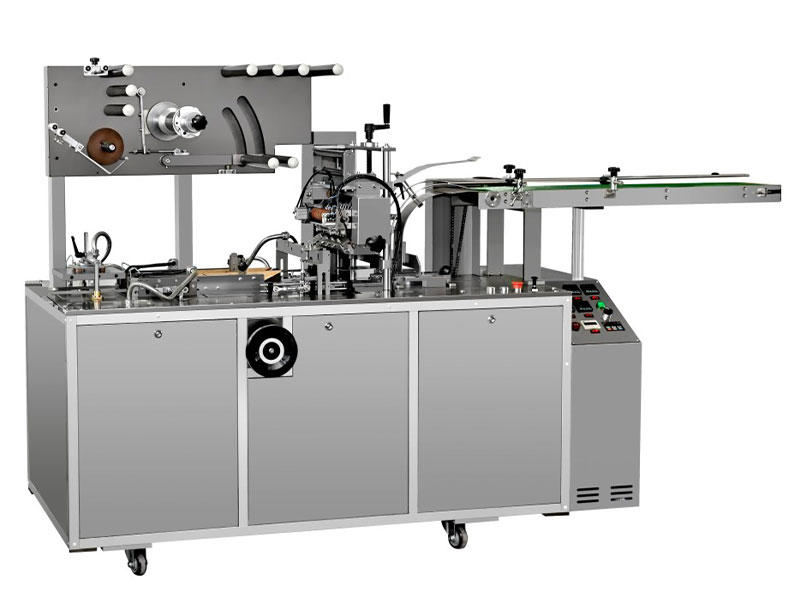

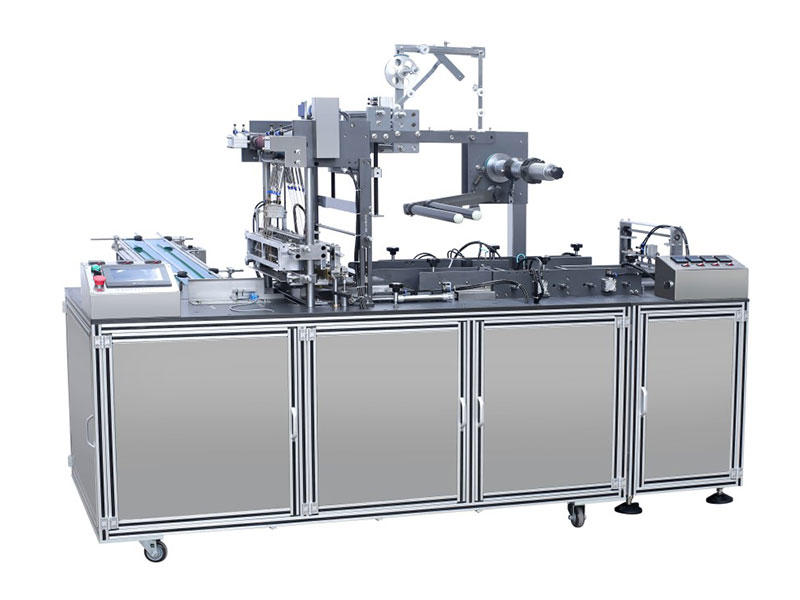

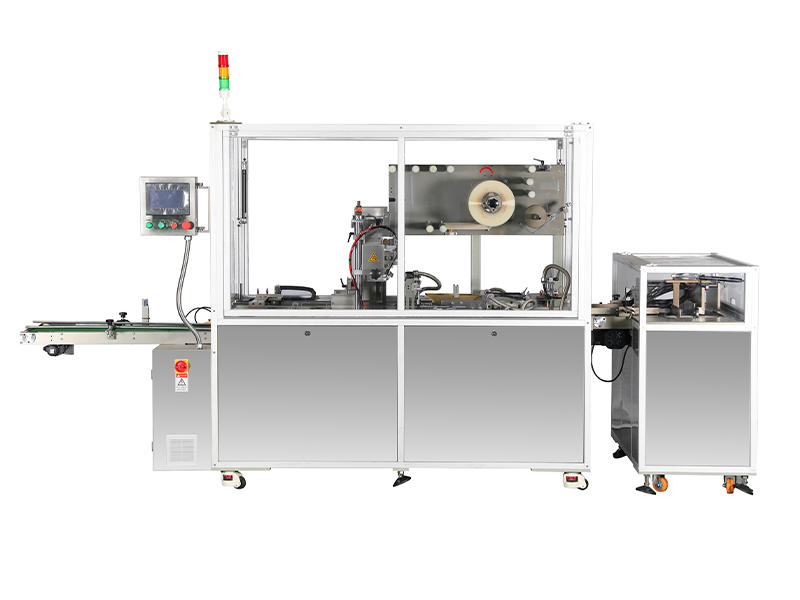

This machine can add the two-side ironing mechanism, the steering mechanism, and the four-side ironing mechanism for the high-temperature belt in the back end according to customer requirements.

This machine can add the two-side ironing mechanism, the steering mechanism, and the four-side ironing mechanism for the high-temperature belt in the back end according to customer requirements.

Full Automatic Cartoning Machines Manufacturer Price For Sale Maker In the realm...

View MoreOEM Full Automatic Cartoning Machines Manufacturer Company In the fast-paced wor...

View MoreSale Full Automatic Cartoning Machines Manufacturer Supplier In the realm of mod...

View MoreChina Full Automatic Cartoning Machines Manufacturer Factory In the dynamic land...

View MoreHigh Quality Automatic Cartoning Machine Manufacturer Maker in China The packagi...

View MoreAutomatic Cartoning Machine Price For Sale Manufacturer Company In the fast-pace...

View MoreTransparent film wrapping machines have emerged as a pivotal technology transforming packaging processes across multiple industries. These machines offer a range of benefits and unique capabilities that significantly impact packaging solutions, driving their preference over conventional methods.

Advantages of Transparent Film Wrapping Machines:

Visibility and Product Presentation: The primary allure of transparent film wrapping lies in its ability to showcase the packaged product. These machines use clear films that provide a full view of the product, enhancing its visual appeal on the shelf and allowing consumers to inspect the contents without opening the package.

Protection and Durability: Transparent films offer protection against dust, moisture, and tampering while ensuring the product remains visible. The films are often robust, providing a secure yet flexible packaging solution that safeguards the product during storage, transportation, and display.

Versatility and Adaptability: These wrapping machines are versatile, accommodating various product shapes and sizes. They can handle irregularly shaped items, providing a snug fit that contours to the product's form, thereby reducing excess packaging material and minimizing waste.

Enhanced Efficiency and Speed: Transparent film wrapping machines are adept at high-speed packaging, significantly improving production efficiency. Their automated processes reduce labor costs and increase throughput, leading to streamlined operations within manufacturing facilities.

Sustainability and Eco-Friendliness: Many transparent films used in these machines are recyclable, contributing to environmentally friendly packaging solutions. Additionally, their ability to use minimal material while maintaining product integrity aligns with sustainability goals by reducing overall packaging waste.

Factors Driving Preference for Transparent Film Wrapping:

Consumer Preferences: In today's market, consumers value transparency and visibility when making purchasing decisions. Transparent film wrapping allows products to be prominently displayed, facilitating consumer trust by offering a clear view of the item's quality and attributes.

Marketing and Branding: Clear packaging enables brands to showcase their products effectively, allowing for creative branding strategies. The visibility offered by transparent films enhances brand recognition and assists in creating memorable packaging experiences for consumers.

Efficiency and Cost-Effectiveness: Transparent film wrapping machines optimize material usage, reducing packaging costs while ensuring effective product protection. Their efficiency in packaging processes leads to cost savings in the long run, attracting businesses looking to improve their bottom line.

Regulatory Compliance: Transparent films often comply with regulations related to food safety and hygiene, making them suitable for industries like food and pharmaceuticals that demand stringent packaging standards.

Technological Advancements: Ongoing advancements in transparent film wrapping machine technology, such as improved film materials, automation, and customization options, continue to drive their preference by offering enhanced capabilities and adaptability.

transparent film wrapping machines represent a pivotal advancement in packaging technology, offering a blend of visibility, protection, efficiency, and sustainability. Their widespread adoption across industries is driven by a combination of consumer preferences, marketing strategies, cost-effectiveness, regulatory compliance, and continual technological innovations. As these machines evolve further, their ability to provide versatile, visually appealing, and sustainable packaging solutions will likely continue to influence the future landscape of product packaging across various sectors.

The integration of transparent film wrapping machines represents a significant transformation in the packaging landscape within the food industry. These machines, equipped with advanced technology and precision, have brought about several pivotal changes, revolutionizing the way food items are packaged and presented to consumers.

Enhanced Visibility and Presentation: Transparent film wrapping machines offer an unparalleled advantage by providing crystal-clear packaging. This transparency allows consumers to have a clear view of the product, enabling them to inspect its quality, freshness, and quantity without having to open the packaging. In the food industry, where visual appeal greatly influences purchasing decisions, this feature significantly enhances the product's presentation on shelves, attracting potential buyers.

Extended Shelf Life and Preservation: The use of specialized films in these wrapping machines helps in preserving the freshness and quality of the packaged food items. Some transparent films come with protective properties that guard against moisture, air, and contaminants, thereby extending the shelf life of perishable goods. This contributes to reducing food waste and enhances the overall quality of the product upon consumption.

Efficient and Cost-Effective Packaging: These machines are designed for efficiency, capable of wrapping numerous items swiftly and consistently. Automation reduces human error and ensures uniformity in packaging, streamlining production processes. Additionally, the use of specific films tailored for different types of food items reduces material waste and optimizes packaging costs, contributing to improved operational efficiency and cost savings for manufacturers.

Compliance with Food Safety Regulations: Transparency in packaging aids in meeting stringent food safety regulations. Consumers can easily verify the contents and ensure that the product adheres to their dietary requirements or restrictions. Furthermore, the use of high-quality, food-grade films that comply with regulatory standards helps manufacturers maintain the integrity of their products and meet legal requirements, fostering consumer trust and brand reliability.

Environmental Sustainability: With growing concerns about environmental impact, the development of eco-friendly, recyclable, or biodegradable transparent films has become a focus. Some manufacturers have started using sustainable materials in these wrapping machines, contributing to reducing plastic waste and aligning with eco-conscious consumer preferences.

the integration of transparent film wrapping machines in the food industry marks a pivotal shift in packaging practices. From enhancing product visibility and freshness to ensuring compliance with regulations and sustainability goals, these machines have a profound impact on various aspects of the food packaging process. Their ability to combine aesthetics with functionality makes them a cornerstone in modern food packaging, catering to both consumer preferences and industry standards.