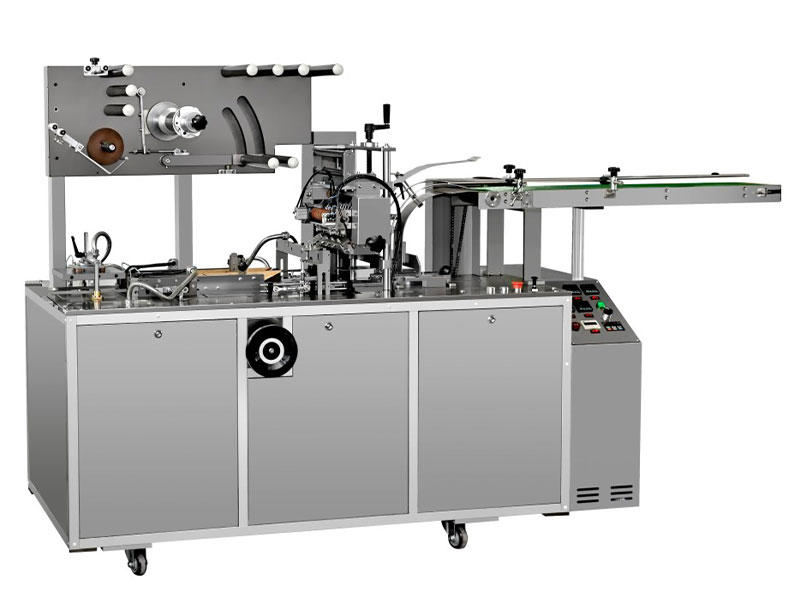

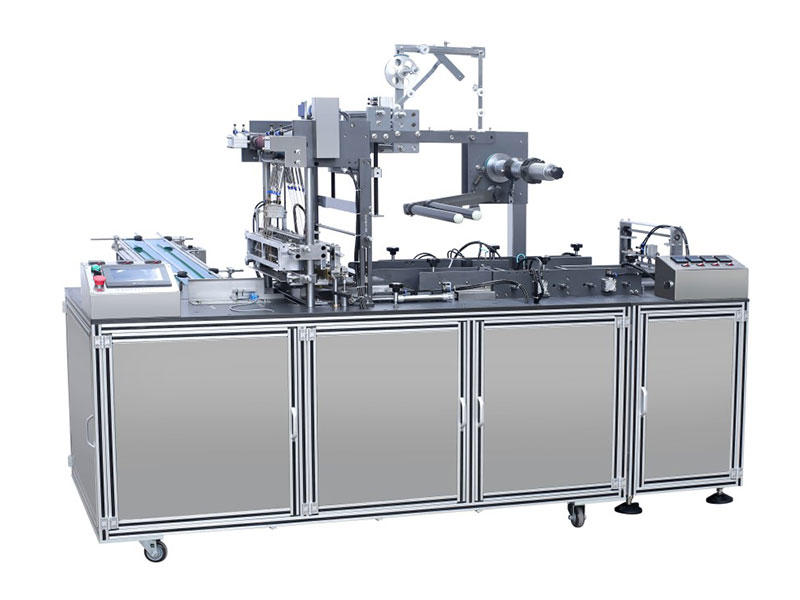

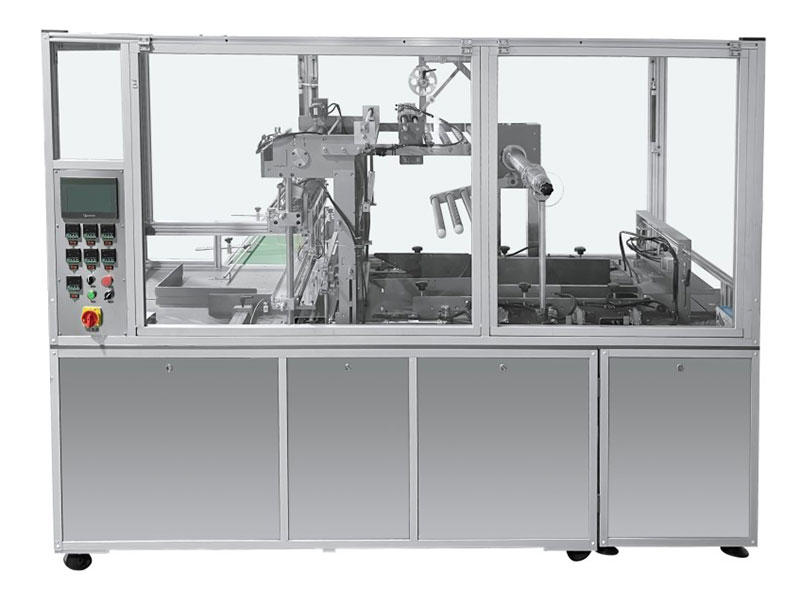

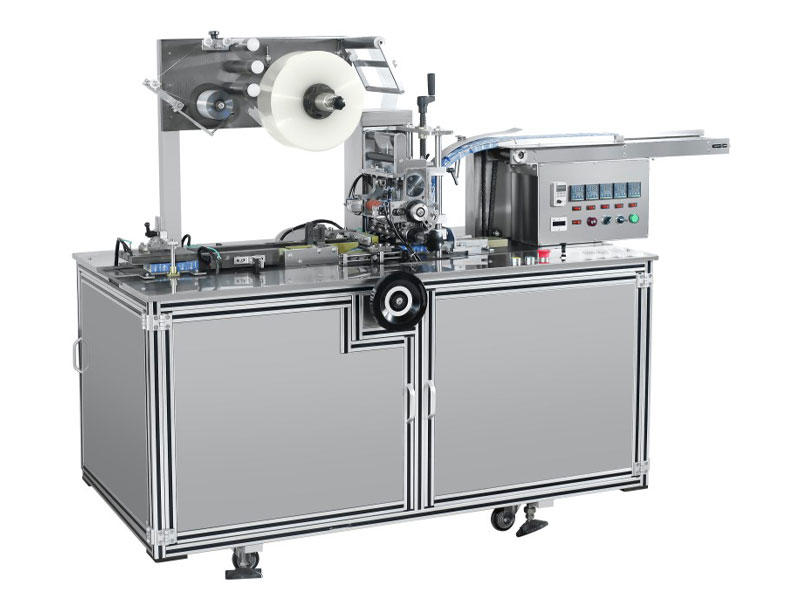

This machine can add the two-side ironing mechanism, the steering mechanism, and the four-side ironing mechanism for the high-temperature belt in the back end according to customer requirements.

This machine can add the two-side ironing mechanism, the steering mechanism, and the four-side ironing mechanism for the high-temperature belt in the back end according to customer requirements.

Full Automatic Cartoning Machines Manufacturer Price For Sale Maker In the realm...

View MoreOEM Full Automatic Cartoning Machines Manufacturer Company In the fast-paced wor...

View MoreSale Full Automatic Cartoning Machines Manufacturer Supplier In the realm of mod...

View MoreChina Full Automatic Cartoning Machines Manufacturer Factory In the dynamic land...

View MoreHigh Quality Automatic Cartoning Machine Manufacturer Maker in China The packagi...

View MoreAutomatic Cartoning Machine Price For Sale Manufacturer Company In the fast-pace...

View MoreThe integration of automated packing machines within the food industry has revolutionized manufacturing processes, significantly enhancing efficiency and productivity. Here are several ways in which these machines have made a profound impact:

Increased Speed and Consistency: Automated packing machines excel in speed and consistency, outperforming manual labor in packaging tasks. They can handle a high volume of products consistently without compromising accuracy, reducing the time required for packaging tasks and ensuring uniformity across all packaged items.

Reduced Labor Costs: By automating packing processes, companies can significantly cut down on labor costs. These machines perform repetitive tasks tirelessly, eliminating the need for a large manual workforce and allowing businesses to allocate human labor to more skilled or specialized areas within the production line.

Enhanced Precision and Accuracy: Automated packing machines are programmed to ensure precise measurements and packaging, minimizing errors and reducing product wastage. This level of accuracy contributes to maintaining product quality and consistency, which is crucial in the food industry to meet regulatory standards and customer expectations.

Flexibility and Adaptability: Many modern packing machines come with the capability to handle various packaging formats, sizes, and materials. They can be easily reconfigured or adjusted to accommodate different products, making them versatile and adaptable to changing production needs without significant downtime.

Improved Safety and Hygiene Standards: Automated packing machines operate within controlled and enclosed environments, reducing the risk of contamination and ensuring higher hygiene standards. Additionally, these machines can be equipped with features like sensors and detectors to identify and reject products that don't meet quality standards, further enhancing food safety.

Data Collection and Analysis: Many automated packing machines are equipped with sensors and software that collect real-time data during the packaging process. This data can be analyzed to optimize production efficiency, identify areas for improvement, and make informed decisions regarding resource allocation and process optimization.

the integration of automated packing machines in the food industry has proven to be a game-changer, enhancing efficiency, productivity, and quality while reducing costs and improving safety standards. Embracing these technological advancements can give food manufacturers a competitive edge in the market by streamlining operations and meeting the growing demands of consumers for consistently high-quality products.

Automated packing machines have become a cornerstone of modern manufacturing, offering unparalleled efficiency, precision, and cost-effectiveness across diverse industries. These sophisticated systems are revolutionizing the production landscape, streamlining processes, and significantly impacting operational capabilities.

Benefits of Automated Packing Machines:

Enhanced Efficiency: Automated packing machines excel in speed and accuracy, capable of handling large volumes of products swiftly and consistently. They significantly reduce packing time, leading to increased productivity and optimized workflow within manufacturing facilities.

Improved Accuracy and Consistency: These machines execute tasks with remarkable precision, minimizing errors in packaging. Consistency in packaging leads to better product quality, reduced waste, and enhanced customer satisfaction.

Cost Savings: While the initial investment in automated packing machinery might be substantial, the long-term cost savings are considerable. Reduced labor costs, decreased errors, and optimized use of materials contribute to significant financial benefits over time.

Versatility and Customization: Modern packing machines offer versatility in handling various product types, shapes, and sizes. They can be easily programmed and adapted to accommodate diverse packaging requirements, allowing for customization without compromising efficiency.

Safety and Ergonomics: Automated packing minimizes the physical strain on workers by taking over repetitive tasks, reducing the risk of injuries associated with manual handling. This contributes to a safer work environment and improved employee well-being.

Challenges in Integration:

Initial Investment and Integration Costs: Acquiring and integrating automated packing machinery involves a substantial upfront investment, including the cost of machinery, installation, training, and potential facility modifications. This cost can be a barrier for smaller businesses.

Complexity and Maintenance: Maintaining and troubleshooting automated systems can be complex. Adequate training and technical expertise are required to operate and address potential malfunctions promptly. Downtime due to maintenance or repairs can impact production schedules.

Adaptability to Changing Needs: While these machines offer flexibility, adapting them to accommodate new packaging designs or product variations might require reprogramming or hardware modifications, potentially causing interruptions in production.

Integration with Existing Systems: Integrating new automated packing machines with existing production systems and software can pose compatibility challenges. Ensuring seamless integration without disrupting ongoing operations is crucial.