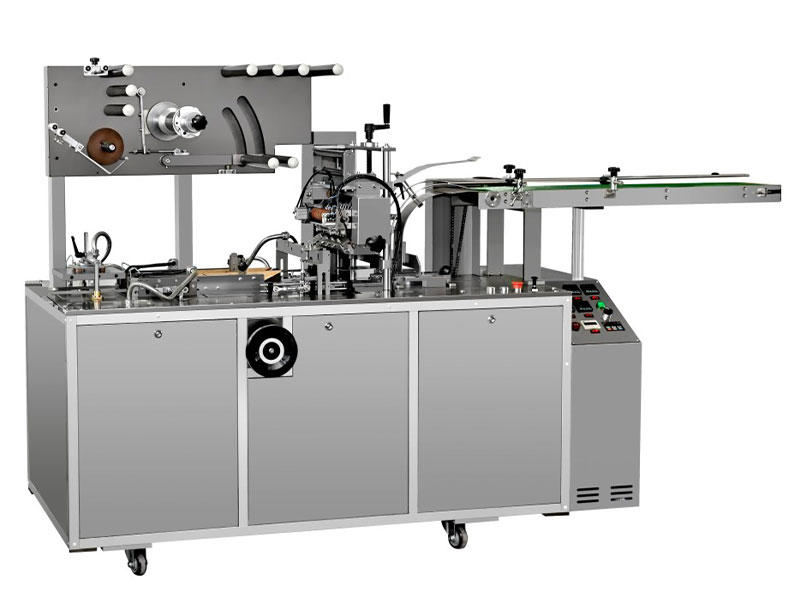

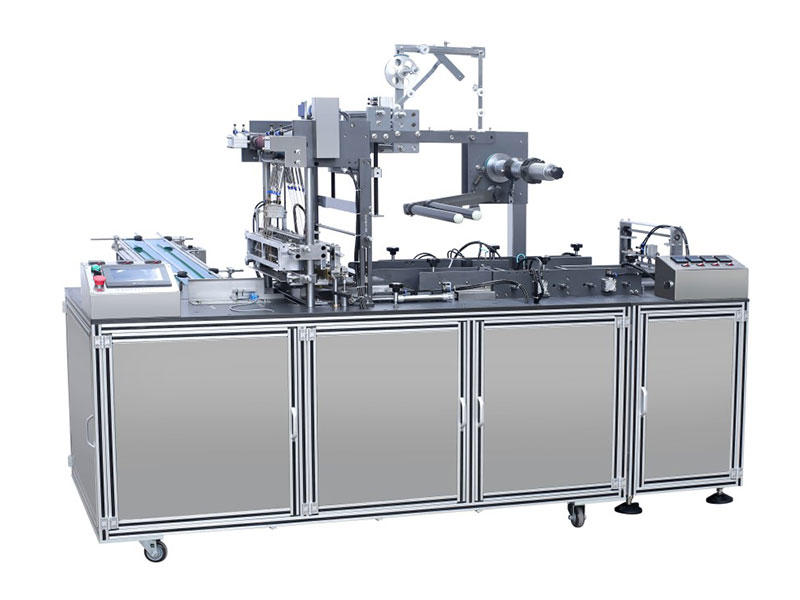

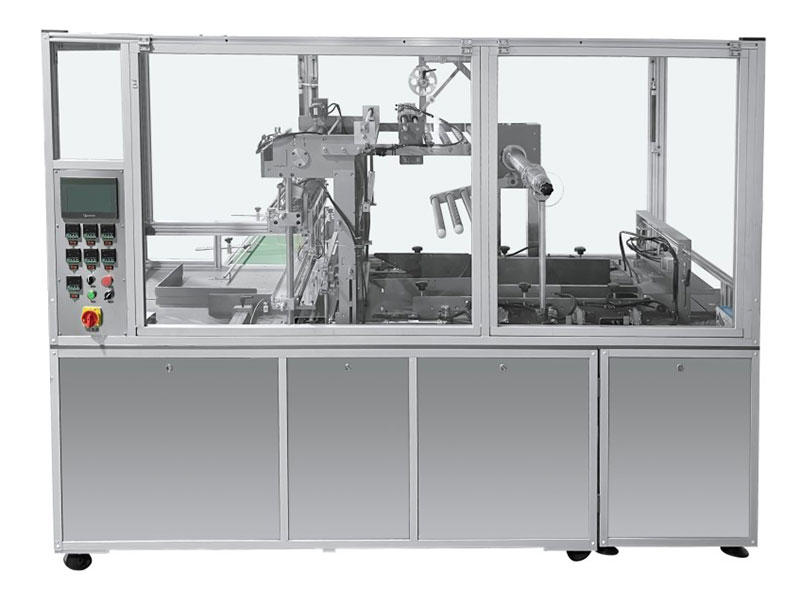

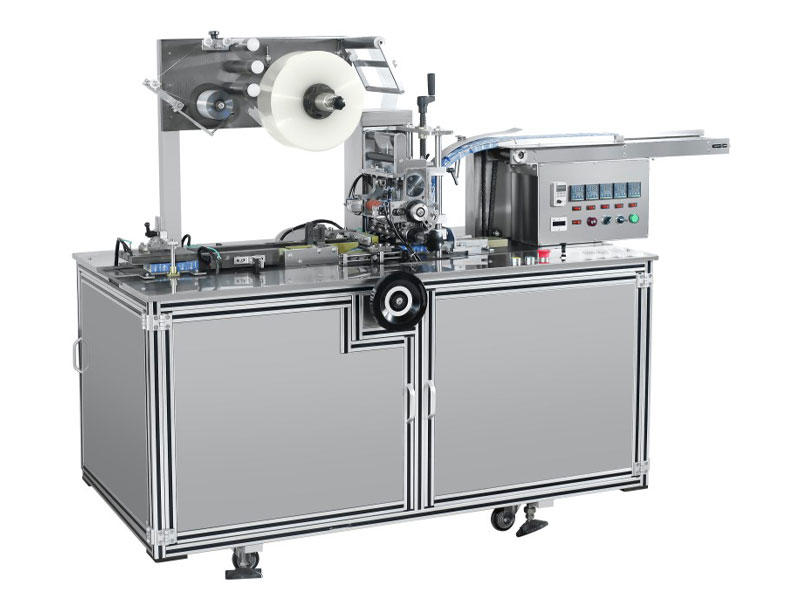

Film Unwinding System

At the heart of the packaging process is the film material itself. The Small Box Transparent Film 3D Packaging Machine begins with the film unwinding system, where a roll of transparent film is securely loaded onto the machine. This component is responsible for feeding the film forward at a consistent rate. Tension control mechanisms are also integrated to prevent wrinkles or uneven film distribution, which can compromise the appearance and seal of the package.

This system often includes adjustable shafts or tension rollers that accommodate different film widths and types, making it flexible for various packaging applications.

Box Feeding and Insertion Mechanism

The second major component of the Small Box Transparent Film 3D Packaging Machine is the box feeding unit, which aligns and transports the products into the packaging position. This mechanism often employs a conveyor belt, push-pull arms, or even robotic arms to ensure each item is properly positioned.

Precision in this stage is vital. If a product is not aligned correctly, the film may not wrap properly, resulting in defects or waste. Sensors and guides help ensure that each small box enters the next phase in the exact right orientation.

Film Cutting and Sizing Unit

After the transparent film is unwound, it needs to be cut into appropriate lengths for each item. The film cutting unit within the Small Box Transparent Film 3D Packaging Machine performs this task. Often operated by a motor-controlled blade or rotary knife system, the unit slices the film based on the dimensions of the product and wrapping specifications.

A programmable logic controller (PLC) usually governs this unit, allowing for automated adjustments in case product sizes change. This feature enhances the machine's adaptability to a variety of small box dimensions.

Wrapping Assembly

This is the core component where the 3D packaging effect occurs. Once the box is in place and the film is cut, the wrapping assembly envelops the box in the transparent film. Using a combination of folding arms, shaping plates, and guiding rails, the machine wraps the film around the product's contours tightly and evenly.

The Small Box Transparent Film 3D Packaging Machine gains its “3D” designation from this precise, box-shaped wrapping that closely mimics the shape of the product, offering a more sophisticated and secure look than simple shrink wrapping.

Heat Sealing and Shrink Unit

The wrapping is not complete until the film is sealed and bonded. The heat sealing unit applies controlled heat and pressure to the film's edges, typically using heated plates or wires. This seals the film layers together and gives the package a neat, tamper-evident finish.

In some variations of the Small Box Transparent Film 3D Packaging Machine, a mild heat shrink process is also integrated to help the film snugly fit the product, enhancing its visual appeal and structural integrity.

Output Conveyor and Collection Section

Once wrapped and sealed, the final product moves to the output conveyor. This section collects the finished packages and either sends them to a collection bin or to the next station in the production line, such as labeling or boxing.

Efficient design in this area ensures a smooth flow of packaged goods and reduces the risk of jams or damage to the finished items.

英语

英语 中文简体

中文简体 阿拉伯语

阿拉伯语