The global packaging industry is increasingly driven by demands for visual appeal, product protection, and operational efficiency. Among the many innovations in this sector, the Small Box Transparent Film 3D Packaging Machine stands out for its ability to wrap products in a clear film that enhances visibility and ensures tight, professional packaging. Particularly effective for small consumer goods such as cosmetics, pharmaceuticals, and boxed food items, these machines have grown in popularity across diverse industries.

As adoption increases, buyers are presented with a range of choices, each offering specific capabilities and configurations. This article explores the various types and options available within the category of Small Box Transparent Film 3D Packaging Machine, providing a structured look at the factors influencing selection and the technical differences that set machines apart.

Understanding the Basic Function

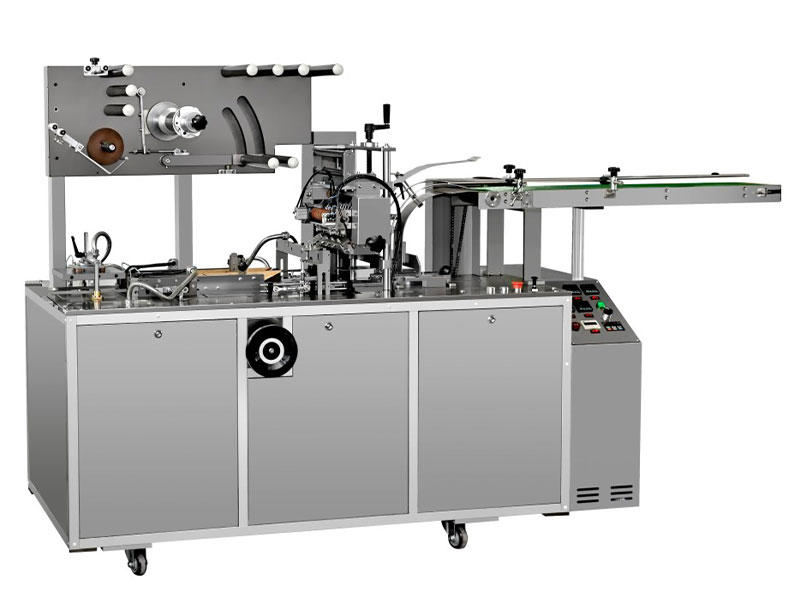

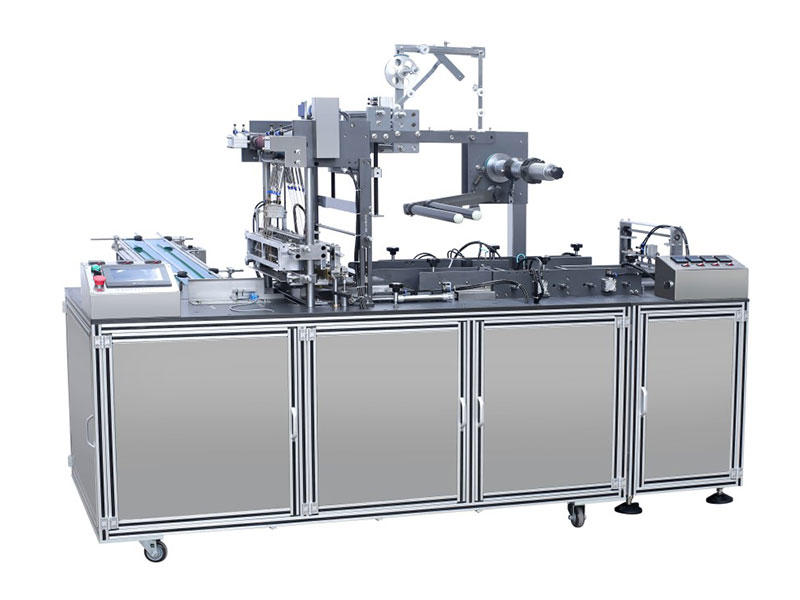

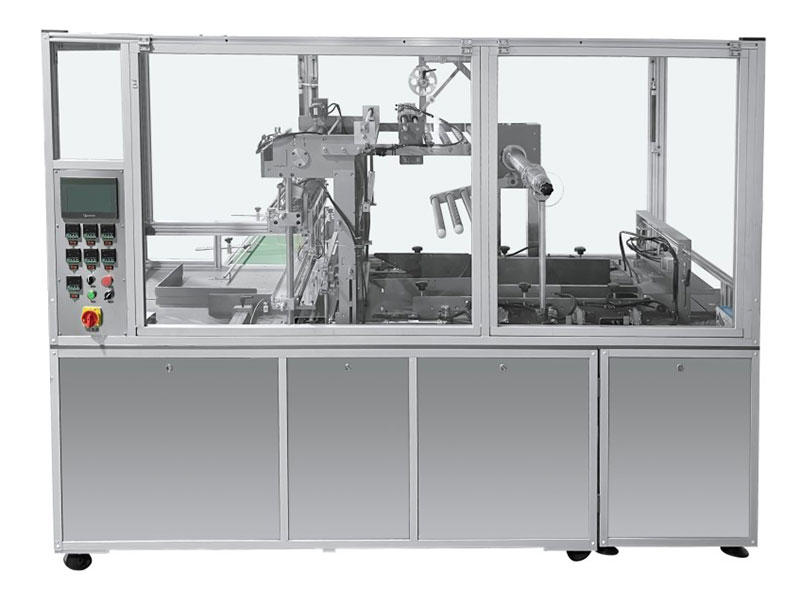

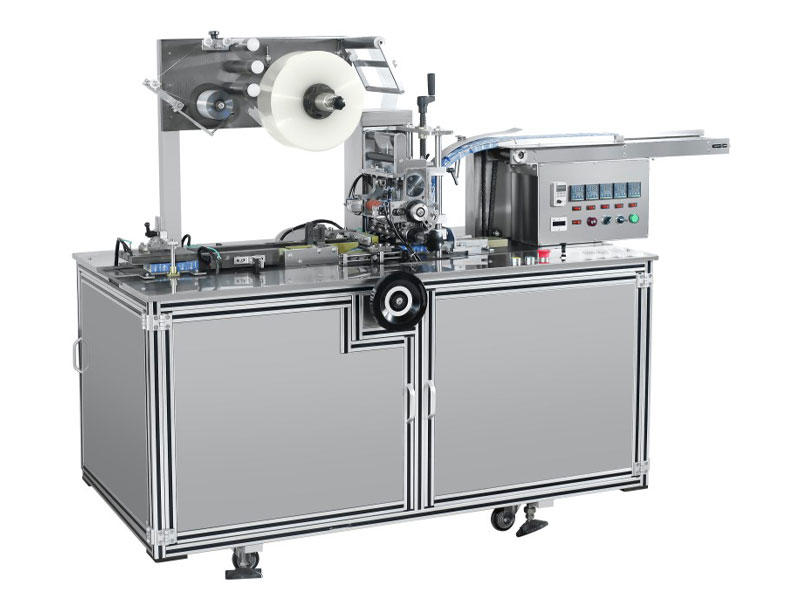

At its core, a Small Box Transparent Film 3D Packaging Machine wraps individual boxes in a transparent plastic film, folding it around the box in a way that mimics the original shape. Unlike traditional shrink-wrapping, this technique gives a more rigid, boxy appearance while still maintaining full visibility of the product. The “3D” designation comes from this form-fitting, multi-dimensional wrap that closely outlines the contours of the packaged item.

This type of packaging machine typically includes several key components: film unwinding and feeding systems, product loading mechanisms, film cutting tools, folding arms, and a heat sealing unit. While these elements are common across models, variations exist that significantly affect performance and cost.

Manual vs. Semi-Automatic vs. Fully Automatic

The major distinction among Small Box Transparent Film 3D Packaging Machine options lies in the level of automation:

Manual Machines – These are the basic, requiring human operators to load products, position film, and initiate the sealing process. While slower and more labor-intensive, they are affordable and suitable for small-scale operations or testing environments.

Semi-Automatic Machines – These models automate some steps (like film cutting and sealing) but still require manual product placement or film alignment. They provide a balance between cost and productivity and are often used by mid-sized businesses with moderate packaging volumes.

Fully Automatic Machines – The advanced category, fully automatic machines handle every step of the process—from product feeding to final discharge—with minimal human intervention. These machines are ideal for high-output operations, offering speed, precision, and consistent packaging quality.

Customization for Product Dimensions

Another key factor in choosing a Small Box Transparent Film 3D Packaging Machine is the range of box sizes the machine can handle. Some machines are built for fixed-size boxes, which can increase efficiency for uniform product lines but limit flexibility. Others offer adjustable settings, allowing businesses to package boxes of different sizes with the same equipment. This feature is especially useful for companies that deal with seasonal packaging changes or multiple product lines.

Material Compatibility

Many machines in this category are designed to work with BOPP (biaxially oriented polypropylene) film, known for its transparency and durability. However, some advanced Small Box Transparent Film 3D Packaging Machine models can also handle eco-friendly alternatives, such as biodegradable films or recyclable materials. This capability is increasingly important for companies prioritizing sustainable practices.

英语

英语 中文简体

中文简体 阿拉伯语

阿拉伯语