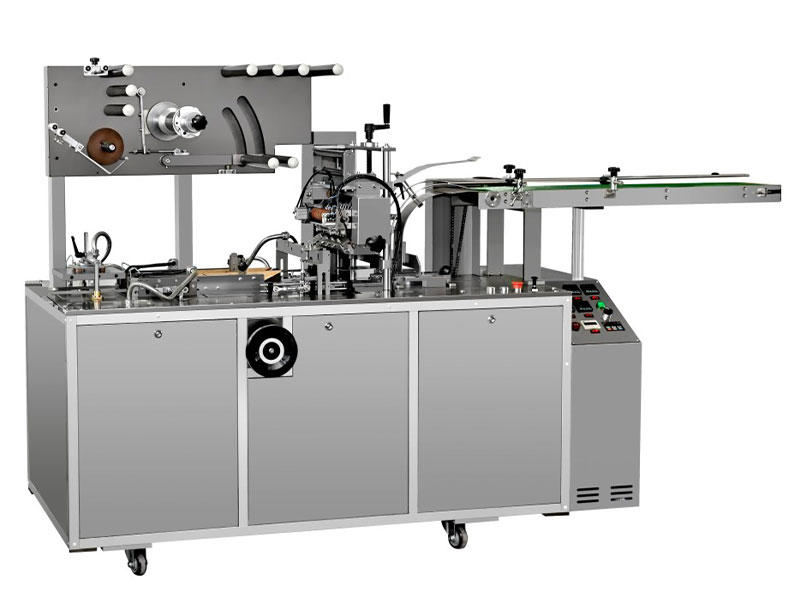

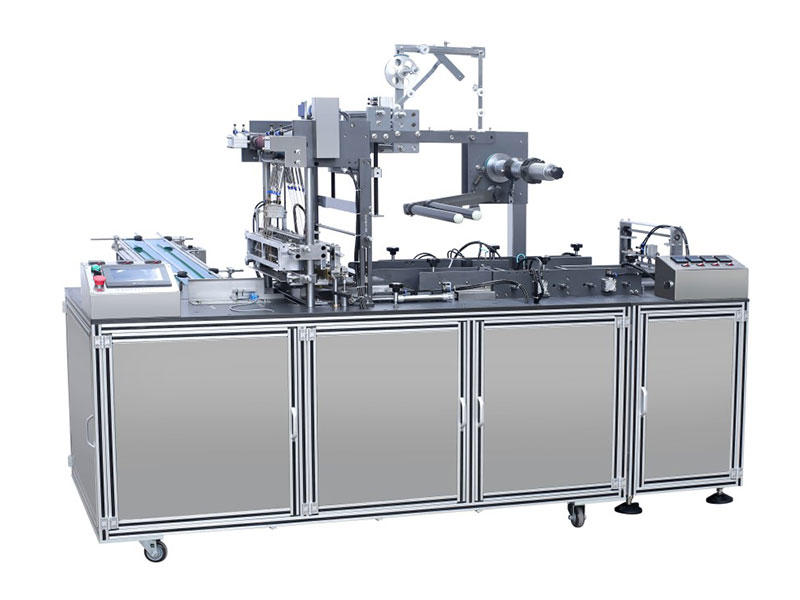

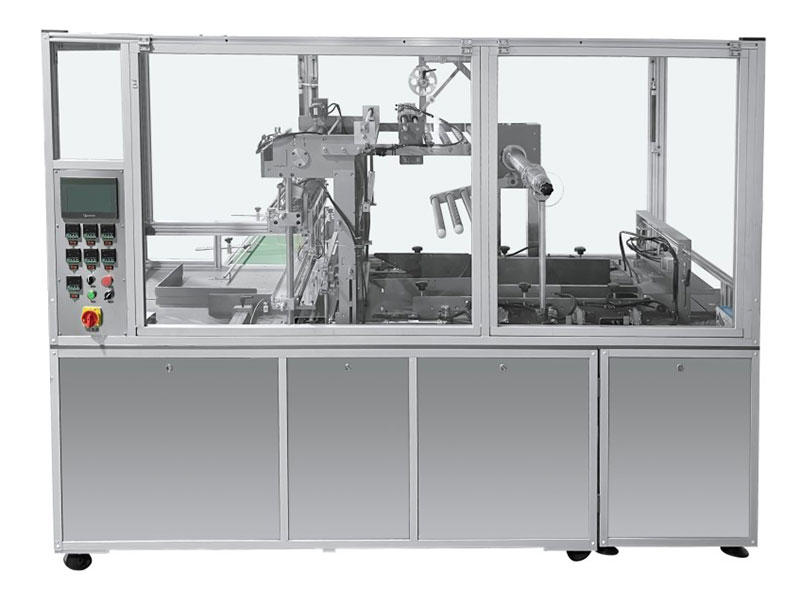

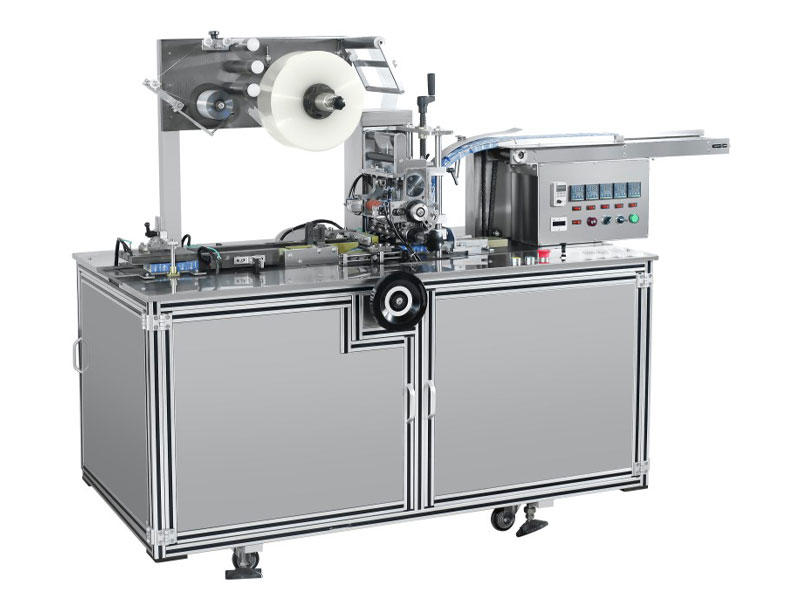

A cartoning machine, also known as a cartoner, is a type of packaging machinery used to erect, fill, and close cartons or boxes. These machines can handle either pre-glued or flat-folded carton blanks and are broadly classified into two types: horizontal and vertical cartoners. Horizontal cartoners typically receive products that are pushed into open cartons horizontally, making them suitable for items such as tubes, bottles, blister packs, or sachets. Vertical cartoners, on the other hand, insert items from the top and are often used for products that can be dropped into the carton, such as loose candies, grains, or small hardware items.

The functionality of a cartoning machine encompasses several stages: feeding the cartons, erecting them into shape, filling them with products, and sealing the filled cartons either by tuck-in flaps, adhesive application, or hot-melt glue, depending on the type and requirements of the product being packed. Some machines also include additional features such as coding and labeling units, quality inspection systems, or automatic rejection of defective packages.

The versatility of cartoning machines makes them applicable across a wide range of industries:

Pharmaceutical Industry: In pharmaceutical packaging, precision and hygiene are essential. Cartoning machines are used to package blister packs, vials, and medicine bottles. These machines are often integrated with inspection systems that check for missing leaflets, verify the presence of barcodes, and ensure the correctness of printed information. This level of control helps maintain compliance with stringent regulatory standards.

Food and Beverage Industry: For perishable and high-volume products such as snacks, cereals, frozen foods, and bottled drinks, cartoning machines enable consistent packaging that maintains product integrity and extends shelf life. Many systems are built to handle variations in carton sizes and are capable of operating at high speeds to match production output.

Cosmetics and Personal Care: In this sector, product presentation and brand image are vital. Cartoning machines contribute to both, delivering neatly packaged items like toothpaste, skincare products, and perfumes in attractive cartons that meet branding specifications.

Consumer Electronics and Household Items: Products like batteries, bulbs, and small devices benefit from the protective and organized packaging facilitated by cartoning machines. These machines ensure items are securely contained, reducing the risk of damage during transport and handling.

The adoption of cartoning machines offers multiple operational advantages:

Improved Efficiency: Automation significantly speeds up the packaging process compared to manual methods. Modern cartoners can handle thousands of cartons per hour with minimal human intervention.

Consistency and Quality Control: Cartoning machines ensure uniformity in packaging, which is critical for maintaining brand standards and customer expectations. Advanced models also incorporate sensors and monitoring systems to detect errors and maintain high quality.

Labor Cost Reduction: By automating repetitive tasks, companies can reduce dependence on manual labor, thus decreasing labor costs and mitigating the impact of labor shortages.

Flexibility and Customization: Today's cartoning machines are designed to accommodate a range of carton sizes and shapes. They are often programmable and can be quickly adapted to new products, supporting short production runs and customized packaging needs.

Integration Capabilities: These machines can be seamlessly integrated into larger production lines, linking with upstream processes such as filling or labeling, and downstream systems like case packing or palletizing.

When choosing a cartoning machine, several practical factors should be evaluated to ensure it aligns with operational requirements. These include:

Type of Product: The nature, shape, and fragility of the product influence the choice between horizontal and vertical cartoners.

Carton Design: Compatibility with different carton sizes, closure methods, and material types should be considered.

Production Volume: High-speed machines are suited for mass production, while smaller, more flexible systems may be better for limited runs.

Ease of Maintenance and Operation: Machines should be user-friendly, with intuitive controls and accessible components for maintenance and cleaning.

Compliance and Validation: Especially in regulated industries, machines must meet safety and hygiene standards and support documentation for audits.

英语

英语 中文简体

中文简体 阿拉伯语

阿拉伯语