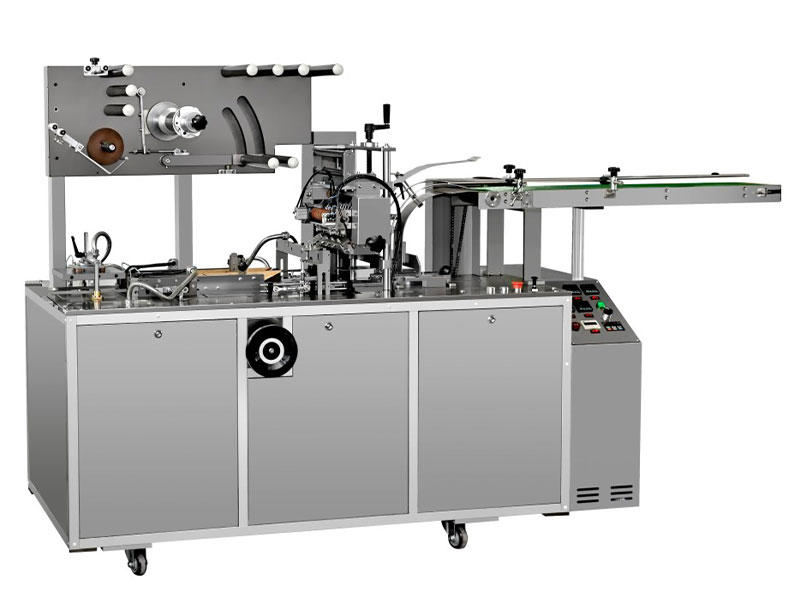

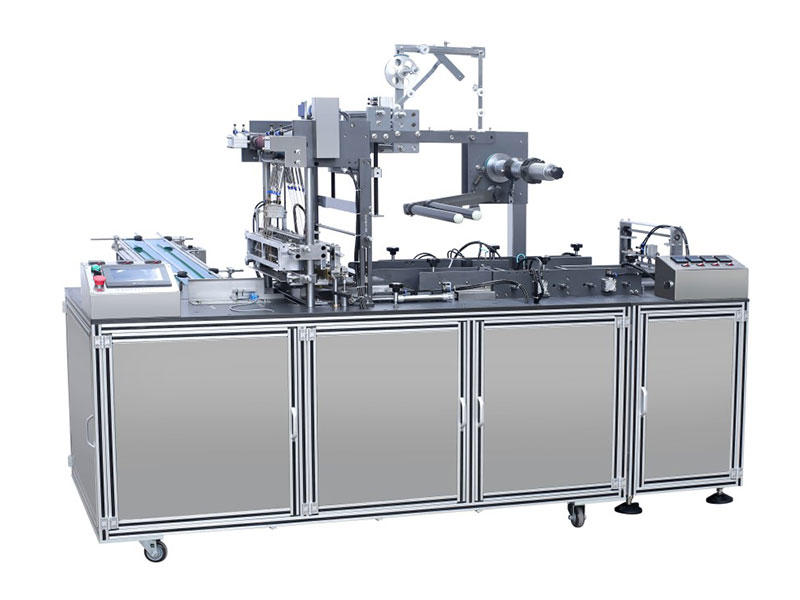

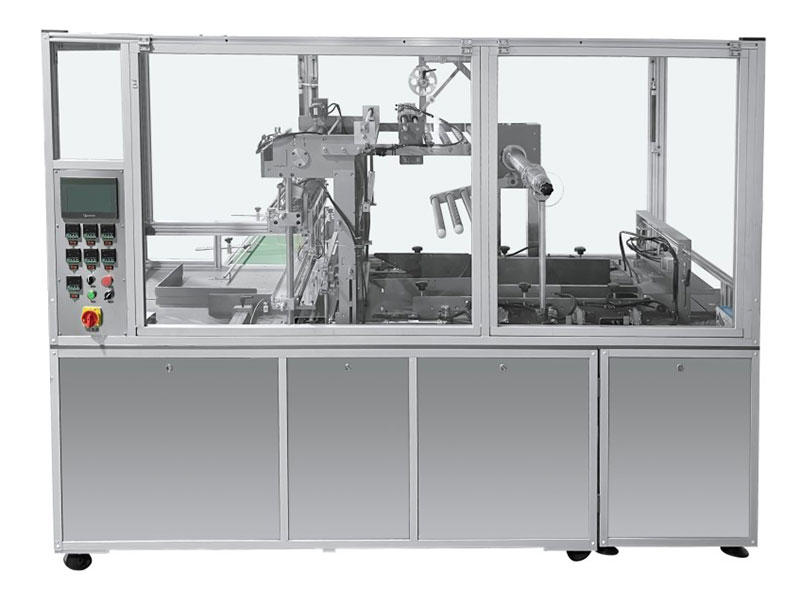

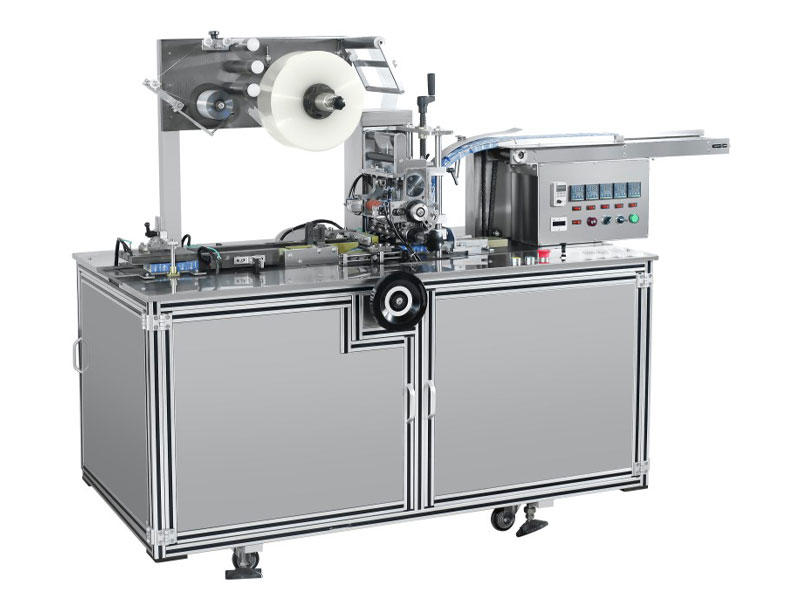

A cellophane wrapping machine is an essential piece of packaging equipment used in industries ranging from cosmetics and pharmaceuticals to food and electronics. It wraps products in transparent or printed cellophane film, providing a professional appearance, protection against external elements, and often tamper evidence. Although it may appear straightforward in function, the machine is composed of several interconnected parts, each with a specific role.

The unwinding system is the starting point of the wrapping process. It holds and releases the cellophane film roll, ensuring consistent tension and alignment.

Film Roll Holder: A mechanical or pneumatic arm that securely holds the roll of cellophane. It is designed to accommodate rolls of various sizes depending on the product dimensions.

Tension Control Unit: Maintains appropriate tension as the film unwinds. It prevents wrinkles or slack that could affect the wrapping quality.

Film Guide Rollers: Help guide the film smoothly from the roll toward the wrapping section, keeping it properly aligned.

The efficiency of the unwinding system directly affects the stability of the entire process, particularly during high-speed operation.

This part ensures that each product is delivered in a synchronized manner to the wrapping area. It includes mechanisms for spacing, alignment, and orientation.

Infeed Conveyor or Belt: Transports products from upstream processes to the wrapping zone. It often features adjustable guides to suit different product sizes.

Product Separator or Timing Unit: Ensures each item is spaced at regular intervals for consistent wrapping. Pneumatic or servo systems may be used depending on the machine's level of automation.

Product Positioning Tray: In some models, products are temporarily held in place on a tray before wrapping begins. This helps maintain accuracy and prevents misalignment.

Proper feeding and positioning are vital for avoiding jams and ensuring uniform wraps.

The wrapping section is the heart of the machine. It manipulates the cellophane film around the product and prepares it for sealing.

Folding Arms or Plates: These components fold the film around the sides, top, and bottom of the product. They may be fixed or movable depending on the machine design.

Film Cutters: A knife or rotary blade cuts the film to the required length for each item. The cutting unit may be mechanical or driven by a motorized system.

Film Lifting Device: This mechanism helps raise the film to wrap taller items effectively. Some machines use vacuum or static control to aid in precise film movement.

This section's synchronization with feeding and sealing systems is critical to ensure wrap accuracy and efficiency.

Once the film is folded around the product, it must be sealed. The sealing unit ensures a neat and secure finish.

Heat Sealing Jaws: These are typically metal bars heated to a specific temperature. They press the film together at the ends or sides to create a bond.

Side Seal Units: In fully wrapped items, side sealers complete the final step of encapsulating the product.

Pressure Adjusters: Help apply consistent pressure during the sealing process. Proper calibration is essential for achieving durable seals without damaging the product or film.

Some machines also offer cold sealing options, especially for heat-sensitive items or specific film types.

英语

英语 中文简体

中文简体 阿拉伯语

阿拉伯语