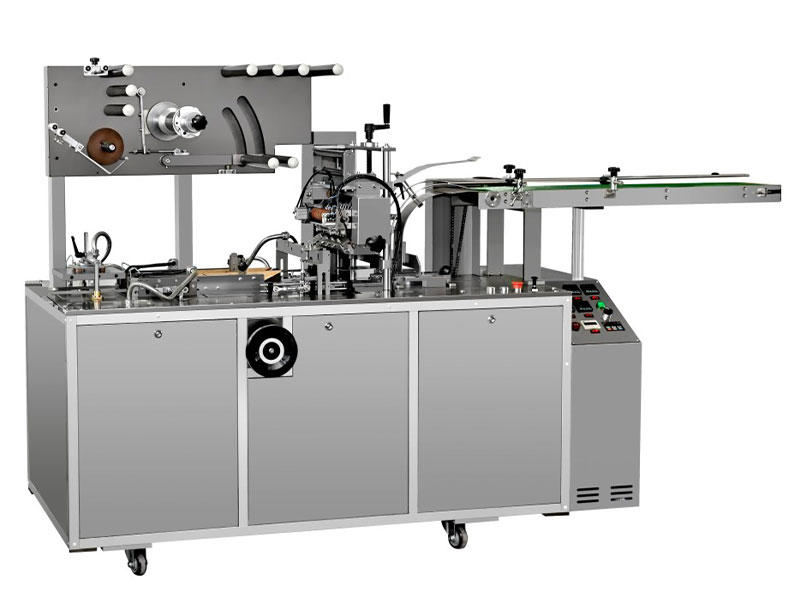

Small Soap Transparent Film 3D Packaging Machine Exporter Producer

By using this machine, small soap transparent film 3D packaging machine manufacturers can create packages that not only safeguard the product but also enhance its visual appeal, making it stand out on store shelves. Additionally, the machine's automation significantly improves packaging speed and consistency, which is essential for large-scale production.

Enhancing Production Efficiency

One of the main values of the small soap transparent film 3D packaging machine is its contribution to enhancing production efficiency. In the past, soap packaging involved manual labor or semi-automated processes that were slow and prone to errors. With the introduction of this machine, manufacturers can significantly reduce the time spent on packaging each soap bar.

The machine is capable of wrapping soap at high speeds, ensuring that production lines can handle large quantities of soap bars in a short amount of time. This increased speed results in higher output and allows soap manufacturers to meet growing consumer demand. Furthermore, the automation reduces the need for manual labor, cutting down on associated costs and freeing up human resources for other tasks in the production process.

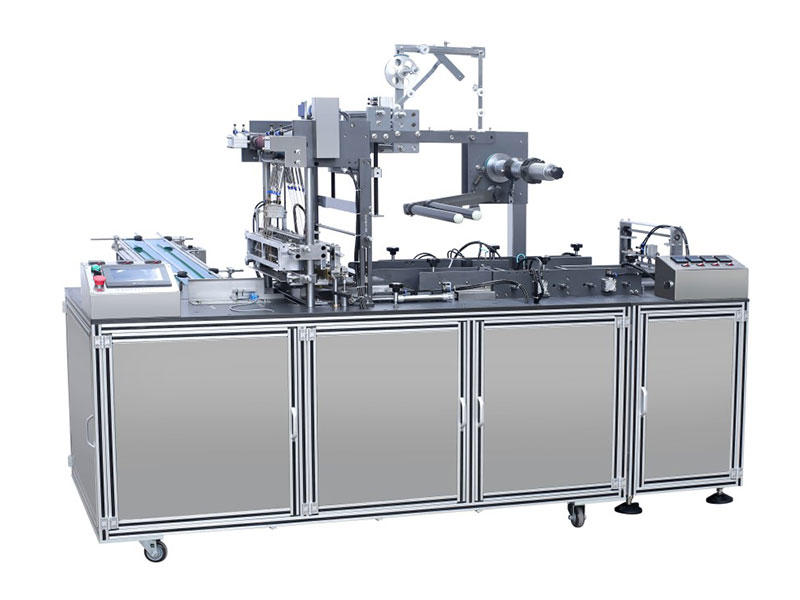

Precision and Consistency in Packaging

Another valuable aspect of the small soap transparent film 3D packaging machine is its ability to produce highly precise and consistent packaging. Traditional methods often resulted in variations in the quality of packaging, with some soap bars poorly wrapped or not sealed securely. This inconsistency could product damage or consumer dissatisfaction.

The automated nature of the small soap transparent film 3D packaging machine ensures that every soap bar is wrapped with uniformity and precision. Each soap is wrapped snugly in a transparent film that is evenly sealed, eliminating the risk of loose or improperly sealed packaging. This consistency not only improves the appearance of the product but also helps to maintain the soap's quality during transportation and storage.

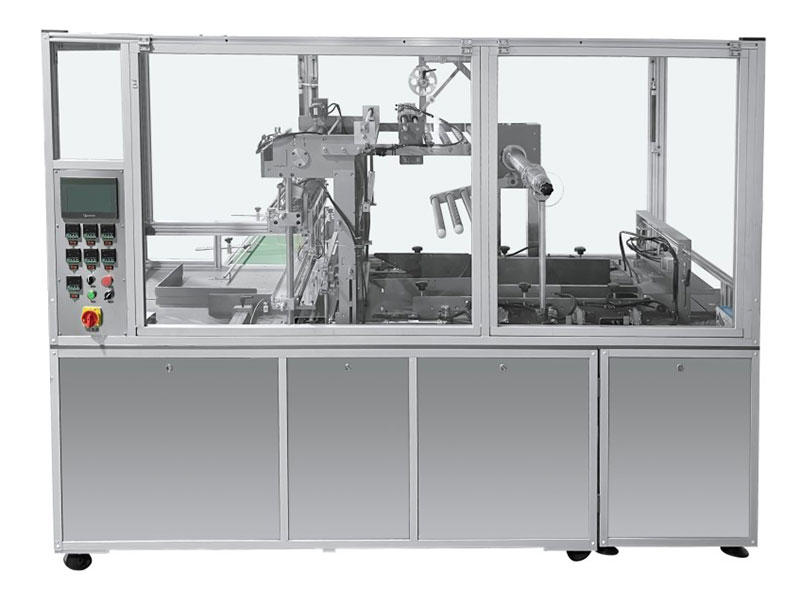

Visual Appeal and Consumer Confidence

The visual appeal of a product is a crucial factor in attracting consumers, and the small soap transparent film 3D packaging machine plays an essential role in enhancing the overall look of the soap. Unlike opaque packaging that hides the product, the transparent film allows the soap to be fully visible. This feature is particularly valuable for luxury or artisanal soaps, where the soap's texture, color, and design are often key selling points.

The 3D effect created by the packaging machine adds an extra layer of sophistication and elegance to the product. Whether the soap has intricate shapes or vibrant colors, the small soap transparent film 3D packaging machine ensures that the product is showcased in the possible light. This transparency builds consumer confidence, as they can clearly see the quality of the product before making a purchase.

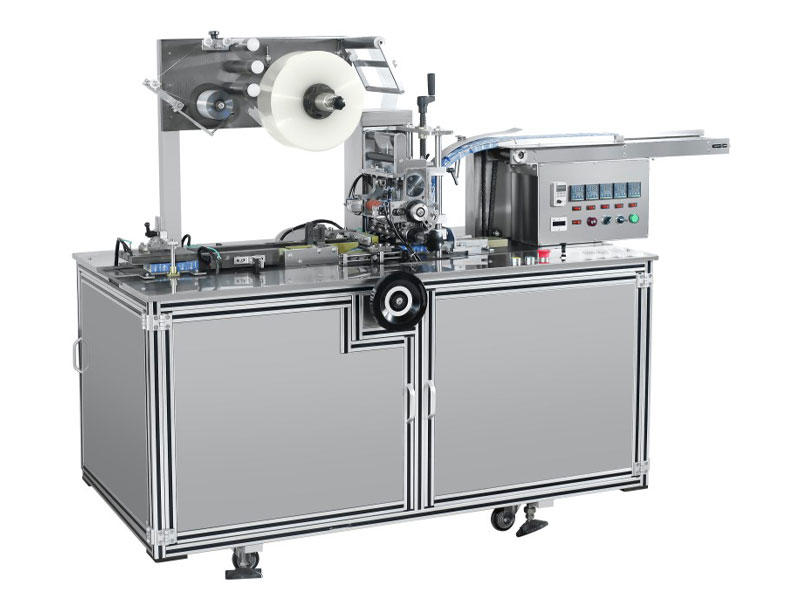

Protection of the Soap Product

While aesthetics are important, the primary function of any packaging is to protect the product inside. The small soap transparent film 3D packaging machine provides a high level of protection for soap bars. The transparent film acts as a barrier against external elements like dust, moisture, and dirt, ensuring that the soap remains in pristine condition from the production line to the consumer's hands.

Additionally, the 3D wrapping tightly seals the soap, preventing it from being exposed to air or contaminants during storage and shipping. This protective feature helps to extend the soap's shelf life, keeping it fresh and free from damage. For manufacturers, this means fewer returns and less waste due to product spoilage or contamination.

英语

英语 中文简体

中文简体 阿拉伯语

阿拉伯语