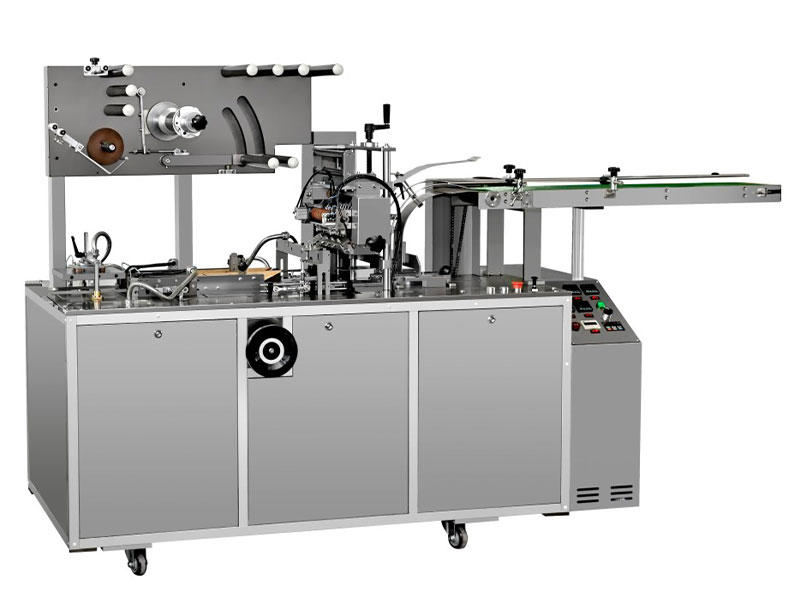

Wholesale Custom ODM Vertical Cartoning Machines Supplier

In the ever-evolving world of manufacturing and packaging, versatility is a prized attribute. Industries require flexible solutions that can adapt to diverse product sizes, shapes, and packaging formats. Among the array of machinery designed to meet these demands, the Vertical Cartoning Machine stands out as a versatile and indispensable tool.

Introduction to Vertical Cartoning Machines: Vertical Cartoning Machines are sophisticated packaging systems engineered to automate the cartoning process, from erecting cartons to filling and sealing them. These machines are employed across numerous industries, including pharmaceuticals, food and beverage, cosmetics, and household goods. Their vertical orientation allows for efficient utilization of space and seamless integration into existing production lines.

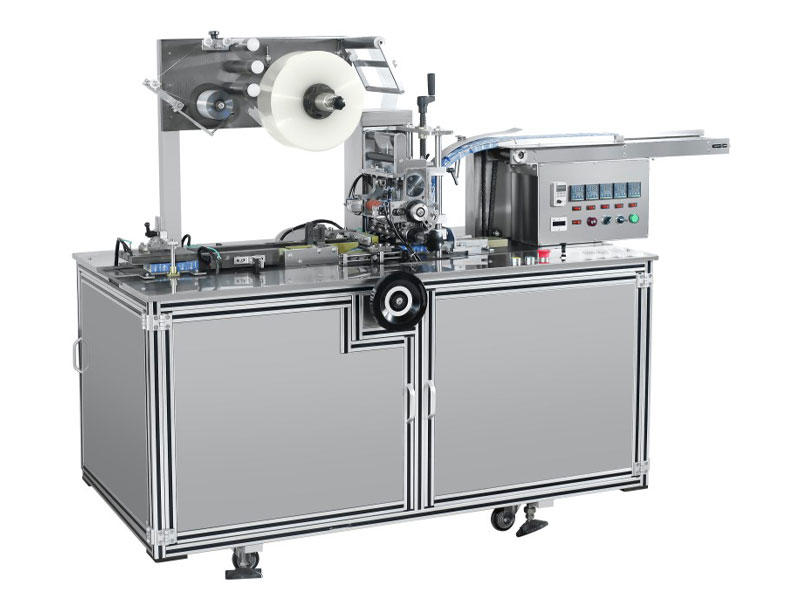

Flexibility in Carton Styles: One of the hallmark features of Vertical Cartoning Machines is their ability to accommodate various carton styles. These machines are designed to handle a diverse range of carton formats, including tuck, glue, and wraparound cartons. Whether packaging bottles, tubes, pouches, or blister packs, Vertical Cartoning Machines offer the flexibility to adapt to different packaging requirements with ease.

Versatility in Product Configurations: Vertical Cartoning Machines are highly adaptable to different product configurations, making them suitable for a wide range of applications. These machines can handle products of various sizes, shapes, and materials, including solid dosage forms, liquids, powders, and granules. Whether packaging pharmaceuticals, snacks, cosmetics, or household items, Vertical Cartoning Machines provide the versatility to accommodate diverse product types.

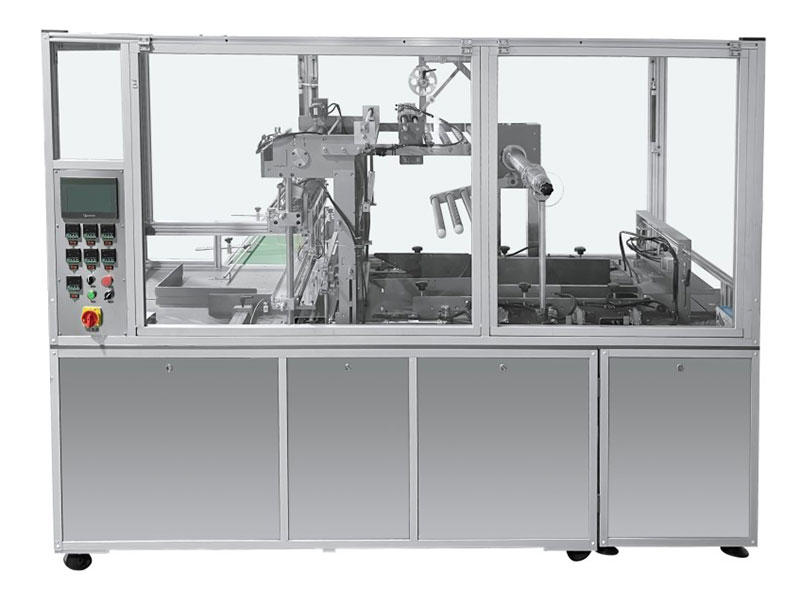

Customization Options: Vertical Cartoning Machines offer customizable features and configurations to meet the specific needs of different industries and applications. Manufacturers can tailor these machines with options such as multiple carton sizes, adjustable filling mechanisms, and customizable sealing methods. This level of customization allows businesses to optimize their packaging processes for maximum efficiency and productivity.

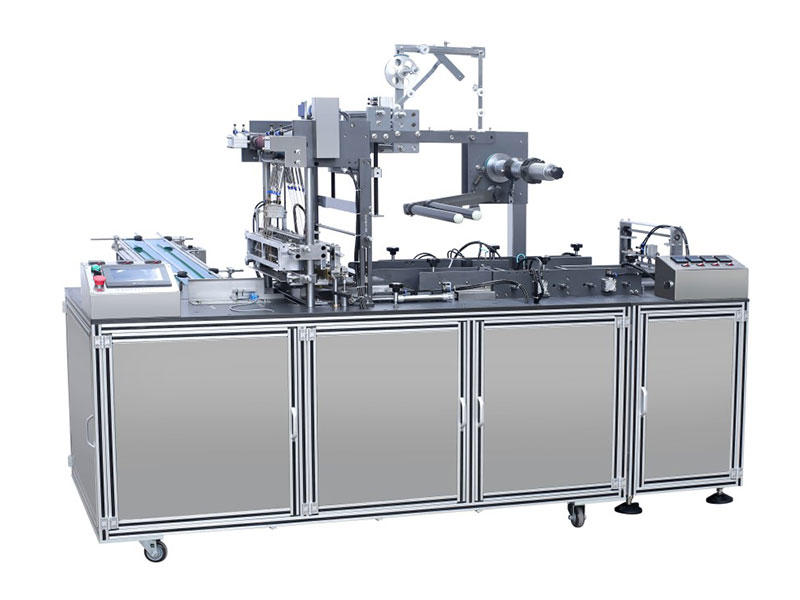

Multi-Functional Capabilities: Vertical Cartoning Machines are equipped with multi-functional capabilities that enhance their versatility and adaptability. These machines can perform a range of tasks beyond basic cartoning, including leaflet insertion, label application, and batch coding. By integrating multiple functions into a single machine, Vertical Cartoning Machines streamline the packaging process and reduce the need for additional equipment.

Quick Changeover: Changeover time is a critical factor in manufacturing efficiency, particularly in industries with frequent product changes or small batch sizes. Vertical Cartoning Machines are designed for quick and easy changeovers between different product runs. Tool-less adjustment mechanisms, intuitive controls, and modular design allow operators to switch between carton sizes, product configurations, and packaging formats with minimal downtime.

Space-Saving Design: The vertical orientation of Vertical Cartoning Machines enables efficient use of floor space in manufacturing facilities. These machines have a compact footprint, making them suitable for installation in tight spaces or crowded production environments. Their space-saving design maximizes the available workspace while maintaining high levels of productivity and throughput.

Integration with Other Equipment: Vertical Cartoning Machines are designed for seamless integration with other packaging equipment, such as filling machines, labeling systems, and case packers. These machines can be configured to interface with upstream and downstream equipment, creating a fully automated packaging line. Integration capabilities enhance efficiency, minimize manual handling, and ensure consistent product quality throughout the packaging process.

Adaptability to Market Trends: In today's rapidly changing marketplace, businesses must stay agile and responsive to shifting consumer preferences and market trends. Vertical Cartoning Machines offer the adaptability needed to meet evolving packaging requirements and market demands. Whether scaling production volumes, introducing new product lines, or incorporating sustainability initiatives, Vertical Cartoning Machines provide the flexibility to adapt to changing business needs.

Cost-Effective Solution: Despite their advanced capabilities, Vertical Cartoning Machines offer a cost-effective solution for packaging operations. Their versatility, efficiency, and productivity improvements result in lower production costs and higher overall profitability. Additionally, the ability to adapt to diverse packaging requirements reduces the need for multiple machines or manual labor, further enhancing cost-effectiveness.

英语

英语 中文简体

中文简体 阿拉伯语

阿拉伯语