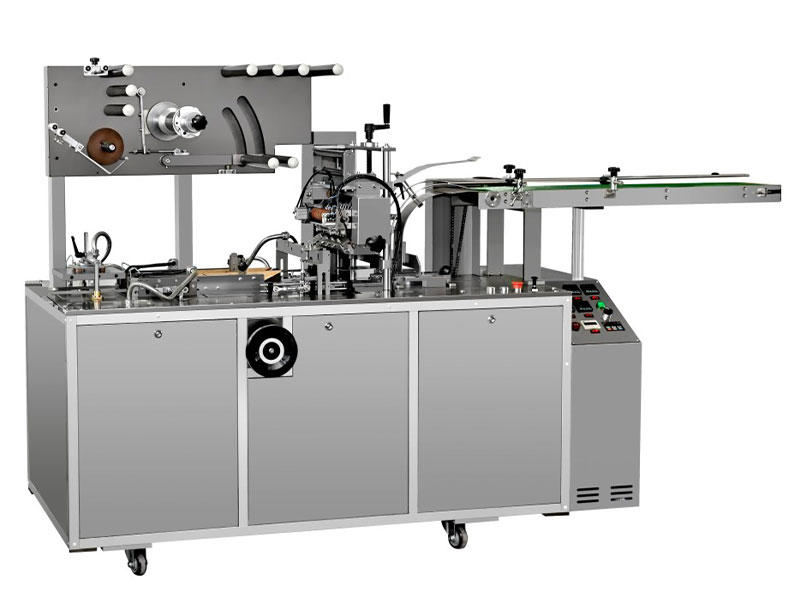

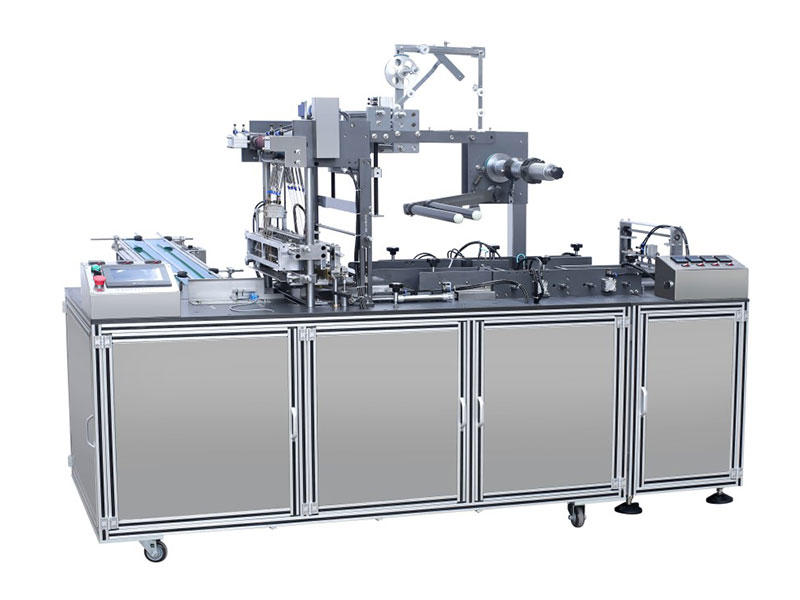

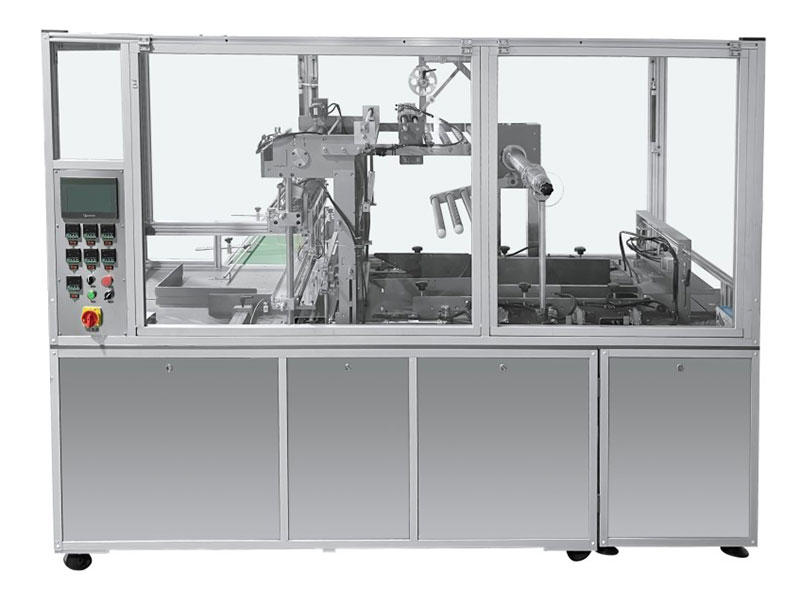

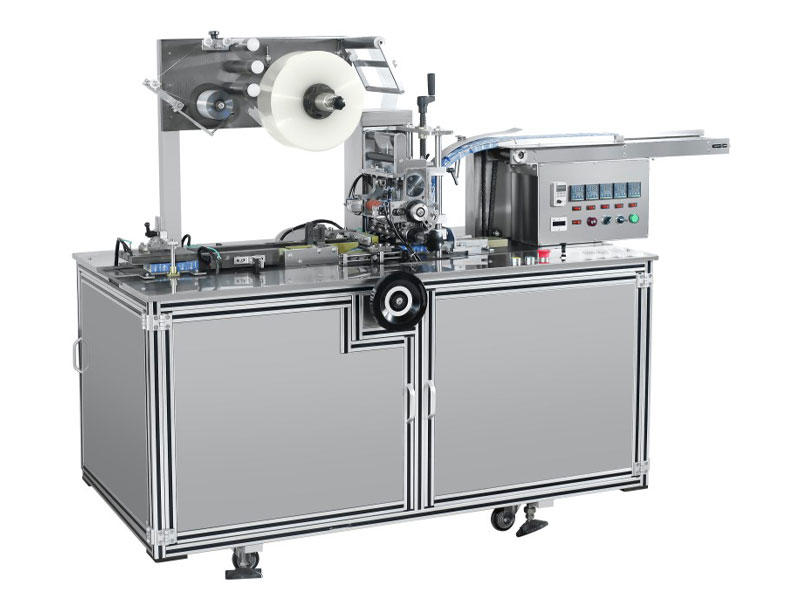

ODM Automatic Carton Taping Machine Price For Sale Company

In today's fast-paced business environment, efficiency is key to success. Whether in manufacturing, warehousing, or distribution, streamlining processes and maximizing productivity are essential for meeting customer demands and staying competitive in the market. One tool that has revolutionized the packaging industry and significantly boosted efficiency is the Automatic Carton Taping Machine. This innovative piece of equipment automates the process of sealing boxes, saving time, labor, and resources while ensuring consistent and secure packaging.

Speed and Productivity:

One of the significant advantages of an Automatic Carton Taping Machine is its ability to significantly increase speed and productivity in the packaging process. Unlike manual taping methods, which rely on human labor and can be slow and inconsistent, automatic taping machines are designed to seal boxes quickly and efficiently. With advanced technology and high-speed mechanisms, these machines can tape dozens of boxes per minute, allowing businesses to process orders faster and meet tight deadlines with ease.

Consistency and Accuracy:

In addition to speed, Automatic Carton Taping Machine offer unmatched consistency and accuracy in box sealing. Human operators may vary in their technique and efficiency, leading to inconsistencies in taping quality and reliability. However, automatic machines are programmed to apply tape with precision and uniformity, ensuring that each box is securely sealed and ready for shipping. This consistency not only improves the overall appearance of packages but also reduces the risk of damage or tampering during transit.

Labor Savings:

Another significant benefit of Automatic Carton Taping Machine is the labor savings they provide. By automating the taping process, businesses can reduce reliance on manual labor and reallocate resources to other areas of operations. This not only reduces labor costs but also minimizes the risk of injuries and fatigue associated with repetitive tasks. With fewer personnel required to seal boxes, businesses can optimize their workforce and increase overall efficiency and productivity.

Customization and Flexibility:

Automatic Carton Taping Machine are highly customizable and adaptable to a wide range of packaging needs and requirements. Whether sealing boxes of varying sizes, shapes, or materials, these machines can be adjusted to accommodate different specifications and preferences. From adjustable tape width and length to customizable sealing patterns and configurations, businesses have the flexibility to tailor the taping process to their specific applications and maximize efficiency.

Space Optimization:

In addition to their performance benefits, Automatic Carton Taping Machine offer space-saving advantages for businesses with limited warehouse or production space. Unlike manual taping stations, which require dedicated workstations and storage areas for tape rolls and accessories, Automatic Carton Taping Machine are compact and self-contained, requiring minimal floor space. This allows businesses to optimize their facility layout and utilize valuable square footage more efficiently.

Enhanced Safety and Ergonomics:

Automatic Carton Taping Machine prioritize safety and ergonomics, reducing the risk of workplace injuries and promoting employee well-being. With built-in safety features such as emergency stop buttons, protective guards, and sensors, these machines minimize the likelihood of accidents and ensure operator safety during operation. Additionally, ergonomic design elements such as adjustable height settings and easy-access controls enhance operator comfort and reduce strain and fatigue during prolonged use.

Quality Assurance:

By automating the box taping process, businesses can achieve higher levels of quality assurance and customer satisfaction. Automatic Carton Taping Machine ensure that boxes are sealed securely and uniformly, reducing the likelihood of packaging errors, leaks, or damage during transit. This enhances the overall presentation of products and reinforces brand reputation for reliability and professionalism. Additionally, consistent and secure packaging minimizes the risk of returns or replacements, saving time and resources in the long run.

英语

英语 中文简体

中文简体 阿拉伯语

阿拉伯语